Flares, Bells, Tees, Els, Wyes, Couplings, & Caps

Fabrications in Butyrate, Polycarbonate, PETG, PVC, and other Thermoplastics

- Funnel Flares

- Bells

- Els

- Tees

- Wyes

- Sleeves

- Couplings

- Custom Fabrications and Fittings

- Threading

Busada makes all kinds of custom plastic tubing, including flared tubing and belled plastics tubing, hundreds of kinds, and we cater to our customer’s unusual needs. We flare and bell butyrate, polycarbonate, PETG, PVC, and other thermoplastics. We also flare and bell our bends.

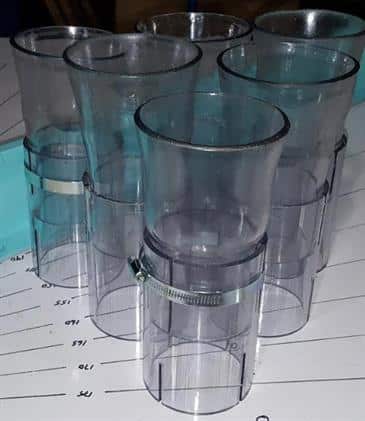

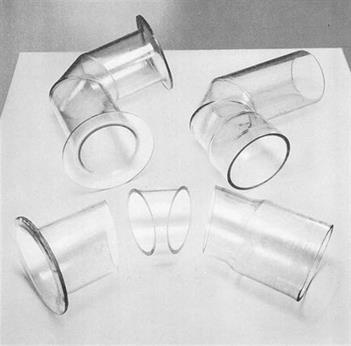

Pictured right: A Sleeved Bell Reducer: We do not recommend connecting tubing and bends with traditional couplings (as in PVC lines). Pneumatic conveyance systems need smooth connections, and the traditional PVC-type coupling joint can damage conveyance materials. As Busada 200 Tubing maintains a .005 tolerance in wall thicknesses, we prefer to make our own coupling sleeves. Pictured above is a solvent-welded sleeve on the flare side with four axial cuts on the sleeve side. The cuts allow for clamping of the sleeve on a straight tube or bend with hose clamps.

Finally, PVC-reducing bushings remain an option. Besides losing transparency, the PVC funnel angle of 30° can bump and ding the conveyance material. Nevertheless, we can flare out tubing to pipe dimensions and bond to PVC.

PVC couplings and bells are fine for valve-stem protectors. Check our blogs on bonding dissimilar plastics with heat and adhesion. Note here that on top of adhesives we recommend a set screw (sheet metal screw) that will bite into the butyrate wall.

PVC pipe often comes standard with bell ends on one side. You can also order belled ends on our Butyrate, Provista (PETG), and Polycarbonate tubing. We have a new process that allows us to make bells to order on hundreds of sizes in small quantities. Thus, tooling and setup costs for custom plastic tubing are reduced to a minimum.

Flare vs Bell

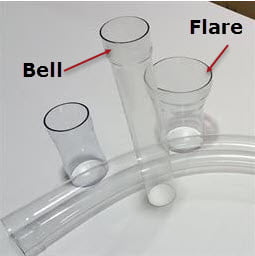

The nomenclature of bells and flares varies throughout the industry. We follow a simple definition.

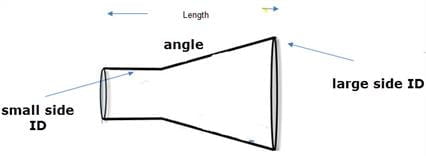

1) A flare is a sloping expansion of a tube. They assist in guiding an object or carrier into the pneumatic tube system. Flares are usually defined by the ID, angle, and lengths.

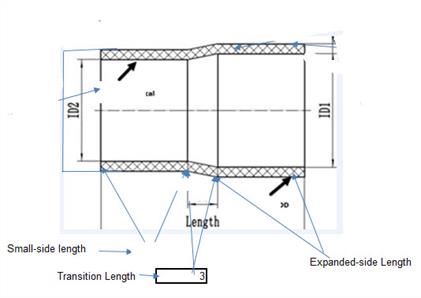

2) A bell is a coupling, an expansion of a tube to couple without a sleeve. The ID of a tube is expanded to its OD. The expansion is not sloping (as in a flare) but is parallel. Standard flares have a 2-3″ transition and 3″ parallel section.

Bells are usually defined by their ID’s and transition length.

We have several blogs on how to couple bells. Flares are not coupled; they are at the beginning and/or end of a pneumatic line.

We can flare or bell all of our transparent tubing products to your needs.

Fabrication of Els and Bells

Here is an illustration showing the method of fabrication of 90° ells from a straight section of CAB Tenite™ clear extruded butyrate pipe.

This example is from 4″ Schedule 40 pipe. The ends of the two pieces to be joined are cut on a 22½° angle. A short filler cut with the 22½° angle on each end is fitted between them. The pipe can easily be assembled in the field, even cut by hand in a miter box. Other fittings can be made in a similar manner using the proper angles cut in the pipe.

Fabricated flanges and bell couplings are also shown. The bell coupling is necessary for installing a pipeline with a bell-and-spigot type of connection.

Flanges can be fabricated directly from the tubing.

Connecting Tubes

Butyrate Tubing Saddles

We are able to fabricate and add to our tubing for a variety of needs. On many occasions, we are asked to cut out different size windows to accommodate different product types in pneumatic conveying. We are asked to create divisions within the tubing itself or modify a length of tubing to specific design specifications.

Tees and Wyes

Often in pneumatic conveyance, one needs to bring two lines together. In such cases, transparency offers obvious advantages; a transparent connector immediately shows a visual of the area most likely to jam.

At Busada we have made various Y’s, T’s, and other custom plastic tubing connectors for decades. Butyrate (CAB) offers not only excellent transparency and clarity but works well with solvent bonding and machining.

Threading

Butyrate, being a cellulosic, is friendly to most fabrications.

We can thread up to 4″ pipe in house. Below we have threaded Tees and Wyes of butyrate used for a hydraulic system. The green color was added during the annealing process (we can add any transparent color or keep it clear). We anneal the tube to strengthen and smooth the threads.