Custom Fabrication

We are flexible, it’s our tubing that’s rigid.

Custom Tubing Fabrication

Creativity and Innovation are woven into the very fabric of Busada. We have developed hundreds of unique and proprietary processes and products. With five profile extruders, a mini extruder, a full-service thermoplastic fabrication department, and an experienced team, we are equipped to work on various thermoplastic prototypes for any kind of custom tubing fabrication needs. Some of our skill sets and resources available include extrusion, blocking, bending, lathing, core-cutting, solvent/UV/and mini extruder welding, routing, sanding, polishing, nearly 20 different kind of saws, and a large stock of clear tube, pipe, and sheet available for fabrication.

As inventors ourselves, we respect your privacy and intellectual property and are happy to sign an NDA. When you choose Busada, you do not only get our high-quality thermoplastics, but you get access to a team of people who have been there and done it…from all facets of manufacturing to patenting, product feasibility studies, crowdfunding, distributing, marketing, shipping, and more. From your first prototype to mass production, we work to earn your long-term business.

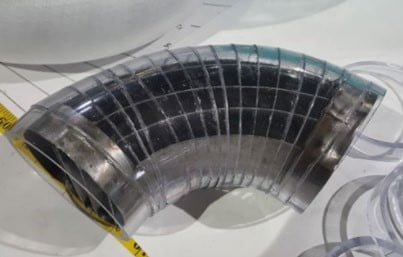

Our customers often come to us with fabrication needs for their tubing. Our clear butyrate (CAB) tubing is a cellulosic that fabricates much like a medium-soft wood. We have the capability to transform our cylinders into various shapes and sizes.

Our transparent butyrate tubing is easily thermoformed, bent, belled, flared, threaded, and blow-molded.

If you need something odd in a tube, a production line, or a display, consider us.

With Busada’s line of straight tubing, bends, and connectors, almost any configuration is possible. Send us your drawing and we will be happy to help bring your project to life.

Proudly Serving Many Clients, Including: