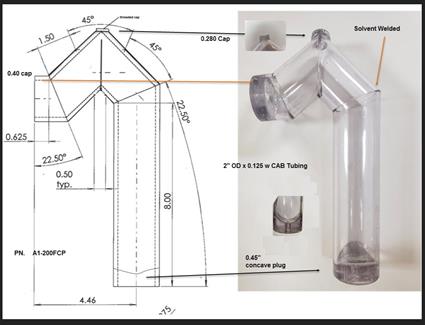

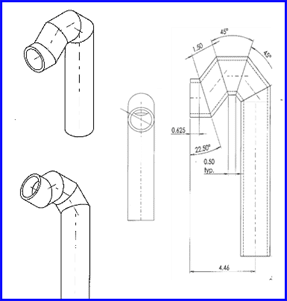

When a request for a custom air filter came in with an associated drawing we got to work. The original print imposed an untenable bend upon the 2″ OD butyrate tube, so we suggested mitering.

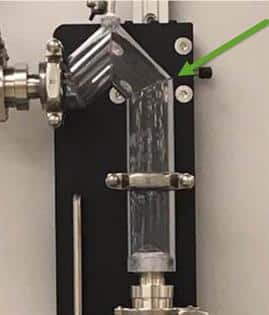

After a bit of back and forth, we suggested another change. As this bong-looking tube was to eliminate air bubbles (and sometimes water) in a system, why not use the miters to our advantage. With the new design, we were able to guide the air easily out of the top through a chimney into a threaded 1/8″ NPT pipe fitting, and guide water out the bottom by using a concave cap (threaded to accept a 3/4″ NPT pipe fitting. The filter was not only to be functional, but attractive for its prototype machine. And, the tolerances were tight; the filter was going into a tight spot and had to fit snugly or the joints would be under undue pressure.

We made a total of four, and look forward to this machine going into production so as to make many more.