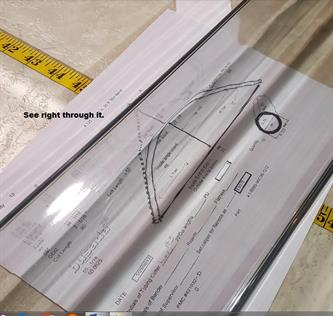

Rectangular transparent tubing formed in an extrusion vacuum system has some inherent problems in clarity. For one, the vacuum sizer heads need extra length to combat the vacuum’s tendency to round the tube. This tends to introduce draglines and chatter marks. We have long been known for the clarity of our rectangular tubing, but now new secondary techniques are producing a very clear and attractive rectangular tube. Below is a picture of a 2.5″ x 4.875″ Inner Dimension CAB (Cellulose Butyrate) Rectangular tube used for a three-tier helix in cup transport. The tube on the left has the normal chatter lines, the tube on the right has gone through our secondary process. Note the difference in clarity.