Over two years ago we received an inquiry from Glenn Stracher, a geologist at EGSC. He needed a plastics tube that could be fabricated and colored to function as a replacement piece for an instrument panel on a classic Chevelle restoration. Glenn gave us constant updates over this two-year restoration process and was kind enough to write the blog himself! Thanks Glenn.

CAB Butyrate Tubing

Solvent Dyed Application to an ABS Automotive Instrument Panel

Glenn B. Stracher1 and Charles J. Busada2

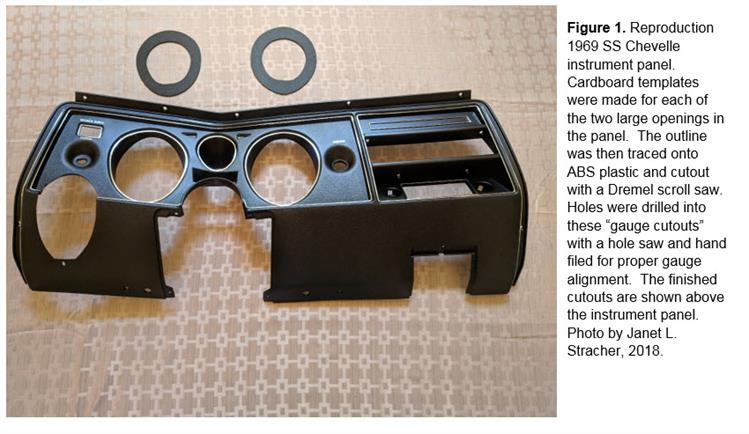

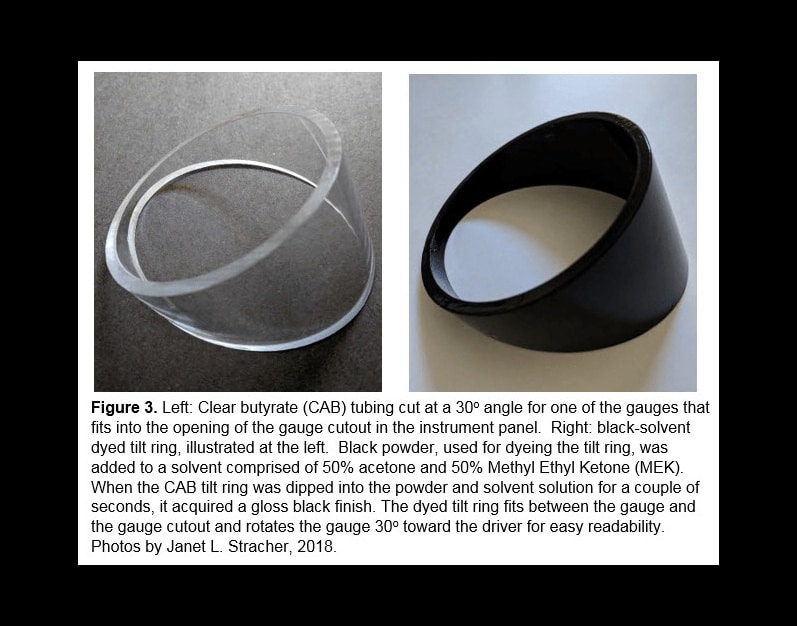

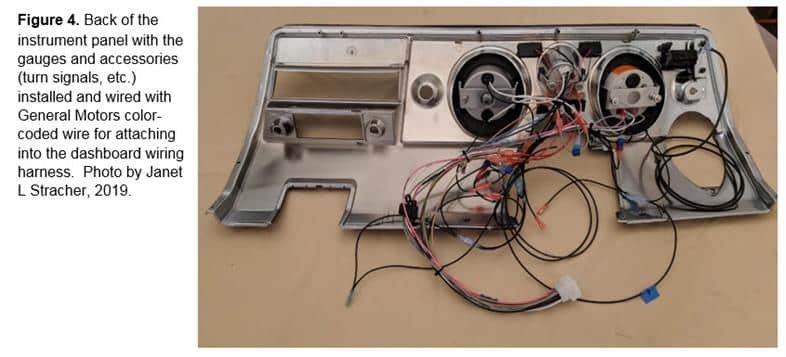

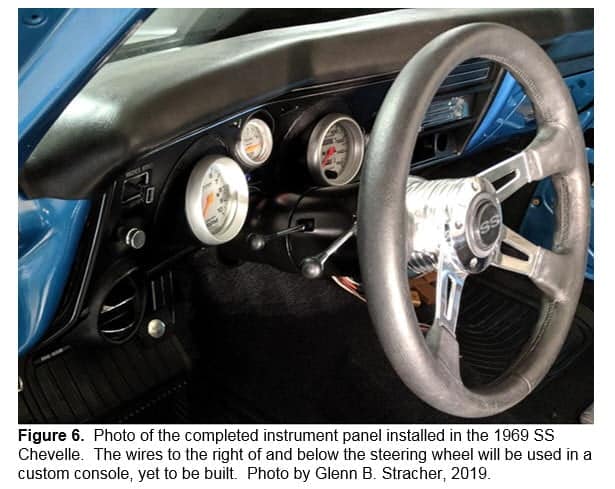

Clear butyrate (CAB) tubing is famous for its friendliness for fabrication and color dyeing. As a case in point, the first author needed automotive gauge tilt rings as part of a project devoted to modifying a reproduction 1969 Chevrolet SS Chevelle instrument panel made of Acrylonitrile Butadiene Styrene (ABS). The tilt rings needed to be cut at a minimum angle of 30° for proper viewing of the gauges from the driver’s seat. The Busada Manufacturing Corporation (BMC) provided the CAB tilt rings for an aftermarket speedometer and tachometer.

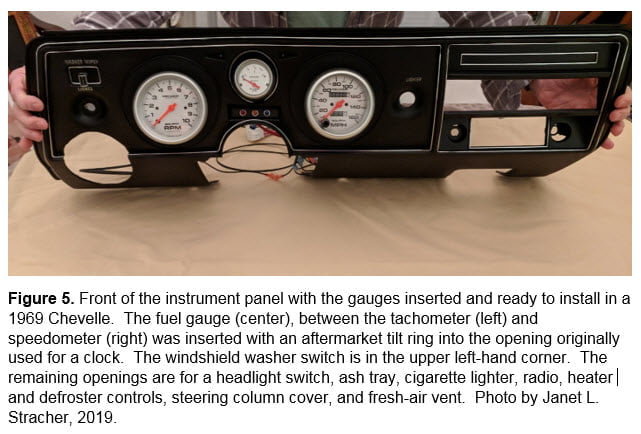

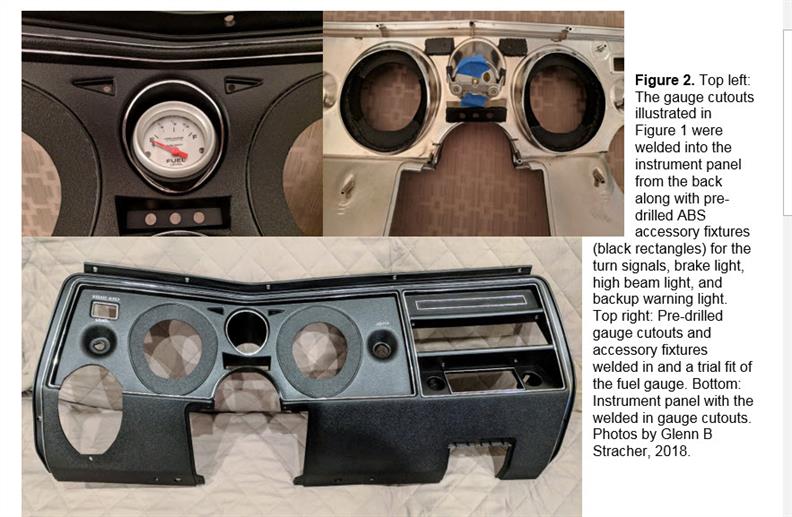

After BMC received illustrations labeled with the necessary dimensions for the tilt-rings, the company provided mitered, clear, transparent Butyrate sections for the gauges. BMC black powder, used for dyeing the tilt rings, was added to a solvent mixture comprised of 50% acetone and 50% Methyl Ethyl Ketone (MEK). When the CAB tilt rings were dipped into the powder and solvent solution for a couple of seconds, they acquired a gloss black finish. The tilt rings, combined with various ABS components welded to the instrument panel from its backside, resulted in a highly modified panel with a legible viewing angle for the gauges.

The included photos and their captions illustrate and describe the modification process of the instrument panel.

1 East Georgia State College, Swainsboro, Georgia 30401, [email protected]

2 Busada Manufacturing Corporation, Louisa, Virginia 23093, [email protected]