A well-known entertainment company contacted us about a special project. They wanted a large OD tube to move along the sides and corners of an amusement building.

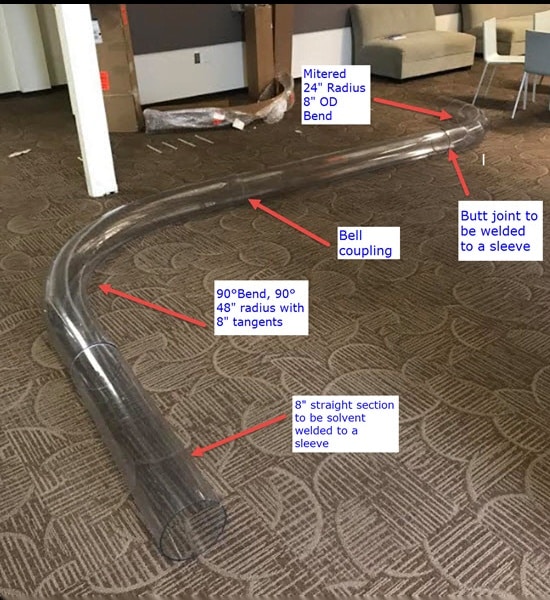

But, their print called for an 8″ OD tube on a 24″ radius. This required a solvent-welded-mitered bend. As you can see from the photo, this design consisted of different welds and 90° bends of different radii.

Mitered bends very strong and with proper solvent welding, we can maintain clarity and smoothness.

Depending upon the number of segments we use, we still remain transparent as we approach round.

Thus, even pneumatic carriers easily maneuver around a proper welded bend.