Currently, we are preparing for a rectangular helical bend for a cup company. They are conveying squat cups and want a holding area for them. Thus, their engineer wants a 2 tier helix where the cups will travel in a vertical position. This would require the “hard bend on the minor axis.”

Here are two links on a 24″ Center-Line Radius Bends, 60° with 3″ tangents.

And the links are joined by a rectangular coupling.

Or, go with the 180Deg bend.

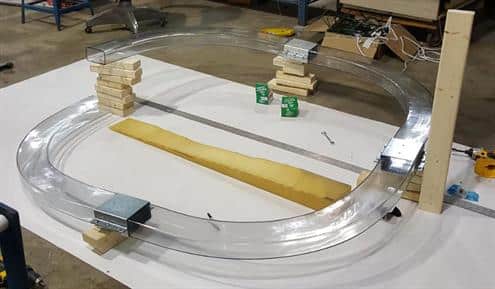

Below is our test on a bend on the minor axis, 24″R 8″ tangents with a 2.5″ rise. Very happy with the result.

Model Stage to the right.

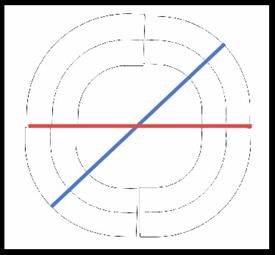

A model comparing the minor bend (blue) with the major bend (clear).

Here is the first tier completed in early March

Here is the first tier of the helix. Notice the set screws in the couplings and the rise.

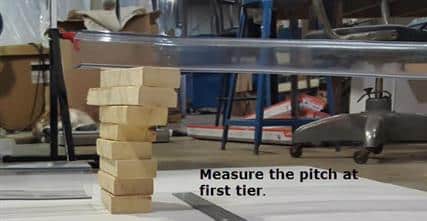

The Helix is never parallel to the ground. In order to enter and exit the helix parallel to the ground, we need a slight bend. The angle rise is about 3.8 degrees and the entire helix rises 12″ in each tier.

The formula for the parallel-bend is Arctan(Pitch/Pi*D) If your cutter diameter = D and your Pitch Angle = A then the pitch will be; P = Pi * D * Tan(90-A)

Helix rise angle at 3.8 deg.