Provista (PETG) tubing, when properly extruded and polished is superior to cast acrylic in every way. When flame polished, it is spectacular for clarity. The picture above shows how a Provista tube shines when flame polished.

This 6″ OD tube, FDA approved and NSF compliant will be used for highly visible storage bins for The Roasting Plant’s coffee houses.

Likewise, COMCO uses a similar flame polish on their banking-system teller tubes.

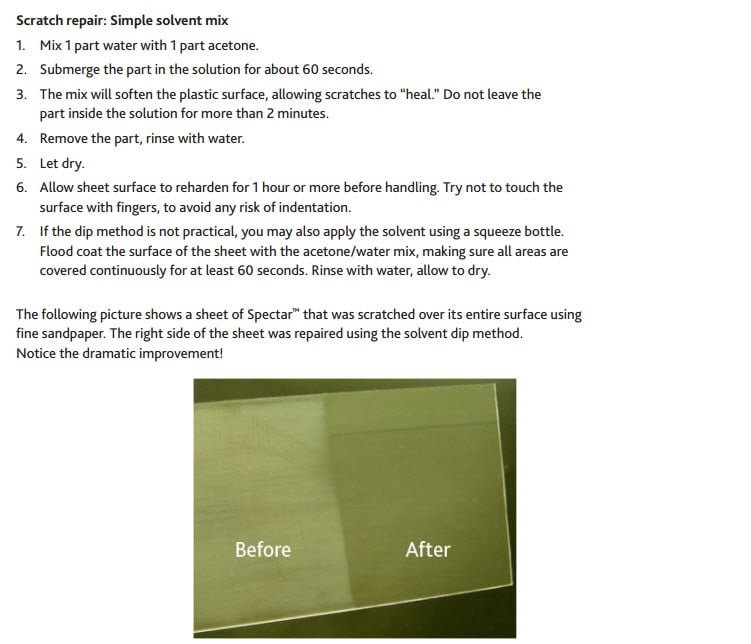

Also, there is the 50-50 acetone water mix.

Provista tubing flame polishes well but is not a good candidate for solvent polishing. The picture to the right shows a flame polish on a 2.375″OD x .237w directly over the saw cut. You’ll see that the polish is not perfect (for that you’ll need to lathe or sand down the cut, but it is a quick improvement that takes only seconds.

One way to fix scratches with Provista is the 50-50 mix of acetone and water. It will not fix deep scratches but does a nice job with scuffs.