Sometimes we just have to be creative when we get calls from damsels in distress. We received a call from such a damsel who needed to replace a worn-out PVC tube and a more worn-out HDPE carrier.

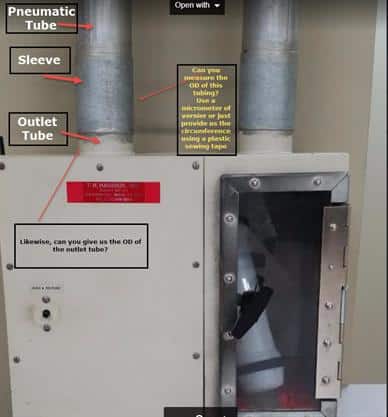

Busada pneumatic tubing consists of three major parts; the tube, the bend, and the sleeve. The tube is designated by Outer Diameter and Wall; from the Wall, we extrapolate the Inner Diameter. The Inner Diameter is crucial to the part being conveyed (it may be a canister, a cup, powder, pellets, caps, etc.) Likewise, a bend’s critical dimension is the Inner Diameter (we are not considering radius here). In order to connect a bend to a straight tube, one needs a coupling. The sleeve, however, has one critical dimension, and that is its Inner Diameter.

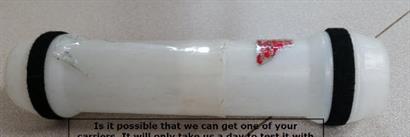

I needed to know the ID of her tube. She was not certain of the ID but sent me a carrier, and you can’t get better than that.

With over 60 sizes of butyrate tubing in stock, we usually can find a match. But not in this case. We can expand, and even decrease a tube diameter.

We were easily able to match the carrier to our transparent tubing, but we needed more; we needed the Outer Diameter of the Outlet Tube. From there we could fabricate a sleeve to connect our clear tubing to her carrier box.

With the PVC tubing out and the new clear transparent tubing in, such damsel was thrilled and is living happily ever after.

In other words, we needed to make a sleeve with the ID of the sleeve = to OD the of the Outlet Tube and our Carrier tube.

Here was our solution:

We used a 2″ OD x 1.875″ ID tube and, with a combination of two sleeves, capped it to a 2.625″ cap. The length was 10″