We now have an option for a hard-baked static dissipative coating for our transparent tubing. Most plastics do not give up their electrons easily; they are insulators. And since they are insulators, they are poor conductors of electricity. Thus, electrical charges can build up on the surfaces and result in a static electrical charge. These electrons are at rest and will move at the first opportunity. Unfortunately, that opportunity may be a worker in the plant who touches the tube at the wrong time. No one likes that zap! So, the object of a dissipative coating is to give the electrons a pathway to move to a ground (which can be a conductive wire wrapped helically around the tube).

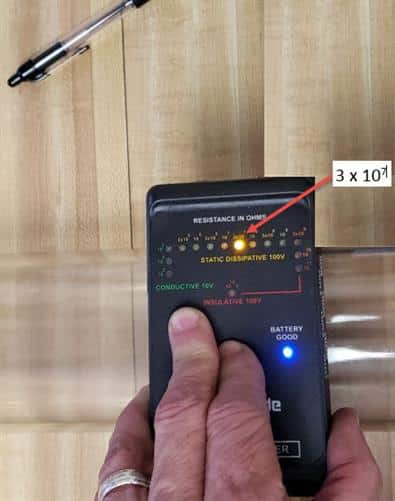

We bake on an acrylic-based coating that has no contaminants, no silicone, and no chlorides. It Meets MILB-81705 for static decay and ANSI ESD S20.20 for static dissipation. It contains no restricted REACH nor RoHS substances. It provides a surface resistivity of 106 to 109 ohms per square.

The coating is a blend of conducting polymers that are inherently dissipative regardless of ambient relative humidity. Unlike surfactants, this Pedot formulation provides dependable protection by allowing static to dissipate safely without wearing off or losing resistivity.

Antistat Grounding method.

We can provide you the Safety Data Sheet and Material Data Sheet upon request.

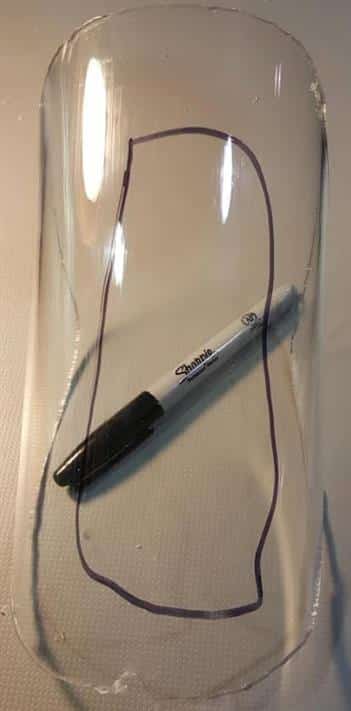

The coating is perfectly clear and is contained within the Sharpie lines below on the PETG tube.

We can add the staticide to any of our extruded products. Prices are based on square footage covered. Call the shop for an estimate at 540-967-2882.

The photograph is of a 4.625″ OD x .125 wall Provista (PETG) tube used in bank-system pneumatic conveyance.

We have data sheets available upon request, or you can go to the ACL Website directly.